- Lack of familiarity with the operational environment makes it harder to assess readiness, select pilot sites or understand where data and connectivity gaps exist.

- Platform, protocol, and vendor choices are often made to address singular problems without considering strategic impact, future-proofing, interoperability, and cybersecurity. This results in significant challenges when IT needs to get involved in support functions.

- Technology deployments happen in isolation without a step-by-step roadmap, or a cross-functional team aligned around a shared vision and execution plan. IT has to perform frequent “Band-Aid” fixes when something goes wrong.

Our Advice

Critical Insight

- CIOs are uniquely positioned to translate operational needs into scalable, secure, and interoperable digital solutions. Without CIO leadership, connected tech initiatives risk becoming disconnected tech experiments.

Impact and Result

- A detailed methodology to select the right use cases fit for current capabilities of the organization.

- List of use cases, case studies, and a primer on connected technology architecture and components.

Modernize Your Manufacturing Operations Using Connected Technologies

Take the right actions to advance the smart factory agenda.

Analyst perspective

Take the right actions to advance the smart factory agenda.

Manufacturers today face rising policy pressures, escalating costs, and a growing talent shortage. Unforeseen crises – such as the COVID-19 pandemic in the past, ongoing geopolitical tensions, and economic fluctuations – continue to disrupt supply chains, while the skills gap, equipment downtime and high maintenance costs threaten operational resilience. Business is demanding for the convergence of physical and digital systems at a rapid pace as manufacturers face pressure to reduce costs, improve productivity, and respond swiftly to market shifts.

CIOs are uniquely positioned to lead the charge in turning connected technologies into a competitive advantage.

Mastering connected technologies requires more than simply deploying new tools; it calls for a cohesive strategy that aligns IT capabilities with business priorities and fosters a culture of digital innovation. For CIOs, this presents both an opportunity and a mandate: to assess the current digital maturity of their organization, build a scalable and secure technology architecture, and champion investments that deliver measurable value.

Connected technologies are essential to advance the smart factory agenda. CIOs will need to identify high-impact use cases, address foundational elements such as cybersecurity, data governance, and interoperability, and play a leading role in workforce transformation and change management. As connected technologies reshape roles and workflows, guiding the organization through this shift by upskilling teams, rethinking legacy processes, and fostering digital literacy will be critical. By taking a proactive and strategic approach, CIOs can position their organizations to fully leverage the benefits of connected technologies, not just as a technology upgrade, but as a catalyst for long-term operational excellence and business growth.

Shreyas Shukla

Principal Research Director, Industry

Info-Tech Research Group

Executive summary

Your Challenge

Lack of familiarity with the operational environment makes it harder to assess readiness, select pilot sites or understand where data and connectivity gaps exist.

Platform, protocol, and vendor choices are often made to address singular problems without considering strategic impact, future-proofing, interoperability, and cybersecurity. This results in significant challenges when IT needs to get involved in support functions.

Technology deployments happen in isolation without a step-by-step roadmap, or a cross-functional team aligned around a shared vision and execution plan. IT has to perform frequent “Band-Aid” fixes when something goes wrong.

Common Obstacles

Procurement decisions are made in silos, and IT is rarely consulted when engineering and operations groups make purchasing decisions for connected technologies.

Not having the appropriate governance structure in place converts simple operational decisions and challenges into constant fire-fighting.

Skills required to support deployments and attend service calls are spread across operations, engineering, maintenance, and IT teams. This slows down the efficiency and efficacy of all stakeholders.

Deployments are site and situation specific, do not scale for other use cases, and do not meet IT standards for data management and cybersecurity.

Info-Tech’s Approach

Convergence comes first. Set up an effective governance structure in collaboration with engineering and operations leaders to cover procurement, operations, and service processes.

IT must conduct an audit of existing systems, data sources, and connectivity gaps to inform integration strategy, avoid duplicative efforts, and build an appropriate response to troubleshooting scenarios.

Update RACI, upskill key staff, and establish a new communication plan to foster adoption and sustain long-term growth.

Choose open, interoperable technologies and design with scalability in mind to support future expansion across sites or functions.

CIOs are uniquely positioned to translate operational needs into scalable, secure, and interoperable digital solutions. Without CIO leadership, connected tech initiatives risk becoming disconnected tech experiments.

Your Challenge

Lack of familiarity with the operational environment

When IT teams lack a deep understanding of the operational environment, it becomes challenging to assess readiness, select appropriate pilot sites, and identify data and connectivity gaps. This disconnect can lead to misaligned technology implementations that fail to address the actual needs of the organization.

Short-sighted platform, protocol, and vendor choices

Selecting platforms, protocols, and vendors to address immediate problems without considering strategic impact, future-proofing, interoperability, and cybersecurity can lead to significant challenges. Such decisions often result in fragmented systems that are difficult to integrate and secure, causing operational inefficiencies and vulnerabilities.

Isolated technology deployments without cross-functional alignment

Implementing technology solutions in isolation, without a clear roadmap or cross-functional team alignment, often leads to fragmented systems that require IT to perform “Band-Aid" fixes when issues arise. This reactive approach not only strains IT resources but also hampers the organization's ability to leverage technology effectively for strategic advantage.

Addressing these challenges requires a holistic approach that emphasizes deep operational understanding, strategic planning, and robust cross-functional collaboration.

Common Obstacles

Siloed procurement decisions excluding IT input

When engineering and operations departments make purchasing decisions for connected technologies without consulting IT, it can lead to fragmented systems that are difficult to integrate and manage. This siloed approach often results in underutilized technologies, redundant solutions, and increased operational inefficiencies.

Lack of appropriate governance structures leading to reactive operations

Without a structured governance framework, operational decisions can become reactive, leading to constant fire-fighting scenarios. This absence of governance results in inconsistencies, overlaps, and gaps among mechanisms, ultimately hindering effective policy enactment.

Dispersed skills across teams slowing deployment support

When the skills required to support technology deployments are spread thinly across operations, engineering, maintenance, and IT teams, it leads to delays and inefficiencies. This dispersion hampers effective collaboration and slows down response times to service calls.

Non-scalable, non-standardized deployments

Deployments that are site and situation-specific, lacking scalability and adherence to IT standards for data management and cybersecurity, pose significant risks and inefficiencies. Such practices lead to data silos, inconsistent data quality, and increased vulnerability to security breaches.

Connected technology maturity isn’t just about software—it’s about people, process, infrastructure, and governance.

Info-Tech’s Approach

Establishing effective governance through IT/OT convergence

Integrating information technology (IT) and operational technology (OT) is essential for creating a unified governance structure that oversees procurement, operations, and service processes. This convergence enhances collaboration between engineering and operations leaders, leading to more cohesive and efficient decision-making.

Conducting comprehensive audits to inform integration strategies

A thorough audit of existing systems, data sources, and connectivity gaps is crucial for developing an effective integration strategy. This process helps identify redundancies, streamline efforts, and establish a robust framework for troubleshooting.

Updating RACI models, upskilling staff, and enhancing communication

Clarifying roles and responsibilities through updated RACI (responsible, accountable, consulted, informed) models, investing in staff development, and establishing effective communication plans are vital for fostering adoption and sustaining long-term growth.

Choosing open, interoperable, and scalable technologies

Selecting technologies that are open and interoperable ensures seamless integration and scalability across various sites and functions, supporting future expansion and adaptability.

CIOs must lead the creation of a shared vision that unites IT, OT, and business around technology outcomes.

Modernize your manufacturing operations using connected technologies

A CIO who owns only IT misses half the opportunity.

Owning value delivery across IT and OT is the future.

Before you proceed

This research is designed to guide connected technology selection in manufacturing. It is not a generic maturity assessment or a technology trend overview.

Rather, it assumes that organizations are serious about taking action and are willing to align strategy, structure, and decision-making accordingly.

To get full value from this research and its accompanying tools, organizations should be prepared with:

- A converged IT/OT governance model that brings together technology, engineering, and operations decision-makers.

- An updated RACI model that clearly defines who is responsible, accountable, consulted, and informed for technology selection, deployment, and support.

- A shared, organization-wide understanding of strategic objectives so that everyone is aiming at the same targets using the same language of value and impact.

With that out of the way, this research is intended for manufacturers spanning all sectors and of all sizes. Given the options available in the connected technology space, we believe there are wins to be had irrespective of the size of the manufacturing footprint or your budget.

Enhance your operational readiness

If you are new to the world of connected operations technology:

- Work with other stakeholders to establish governance frameworks that align IT and OT priorities, ensuring collaboration, compliance, and strategic oversight across both domains.

- Focus on enabling real-time OT visibility while implementing robust cybersecurity measures to protect connected assets and data.

- Expect challenges and prepare to address them the right way.

These resources will strengthen your readiness for connected technology selection.

If you are looking to manage governance of a converged IT/OT ecosystem effectively, see Improve OT Governance to Drive Business Results.

If you are looking to mature your project portfolio management (PPM) practices in preparation for connected technology initiatives, see Improve Your PPM Maturity Holistically Across IT/OT.

If you are looking to improve your cybersecurity posture to include connected technologies, see Secure IT/OT Convergence and Understand Modern Cybersecurity Solutions for Manufacturing IT & OT.

If you are looking to explore potential challenges you can expect to encounter, see Mitigate the Challenges of Industry 4/5.

Blueprint deliverables

Key deliverables:

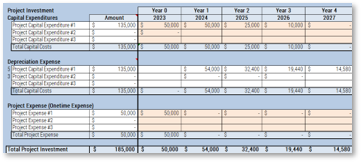

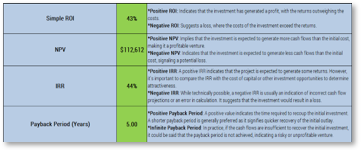

Manufacturing Modernization Financial Analysis Tool

This tool allows you to analyze your planned investments in connected technologies by assessing its total cost of ownership and ROI.

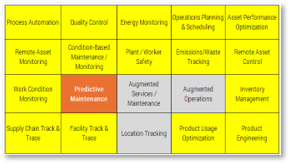

Manufacturing Modernization Use Case Selection Tool

This tool allows you to select use cases for implementation based on your current state and immediate business needs.

Each step of this blueprint is accompanied by supporting tools and deliverables to help you accomplish your goals.

Using the financial analysis tool…

Understand the investment required.

Perform breakeven analysis, calculate ROI, NPV, and IRR.

Using the use case selection tool…

Understand which use cases match your current operational readiness.

Build an implementation roadmap by prioritizing quick wins.

Insight summary

CIOs are uniquely positioned to translate operational needs into scalable, secure, and interoperable digital solutions. Without CIO leadership, connected tech initiatives risk becoming disconnected tech experiments.

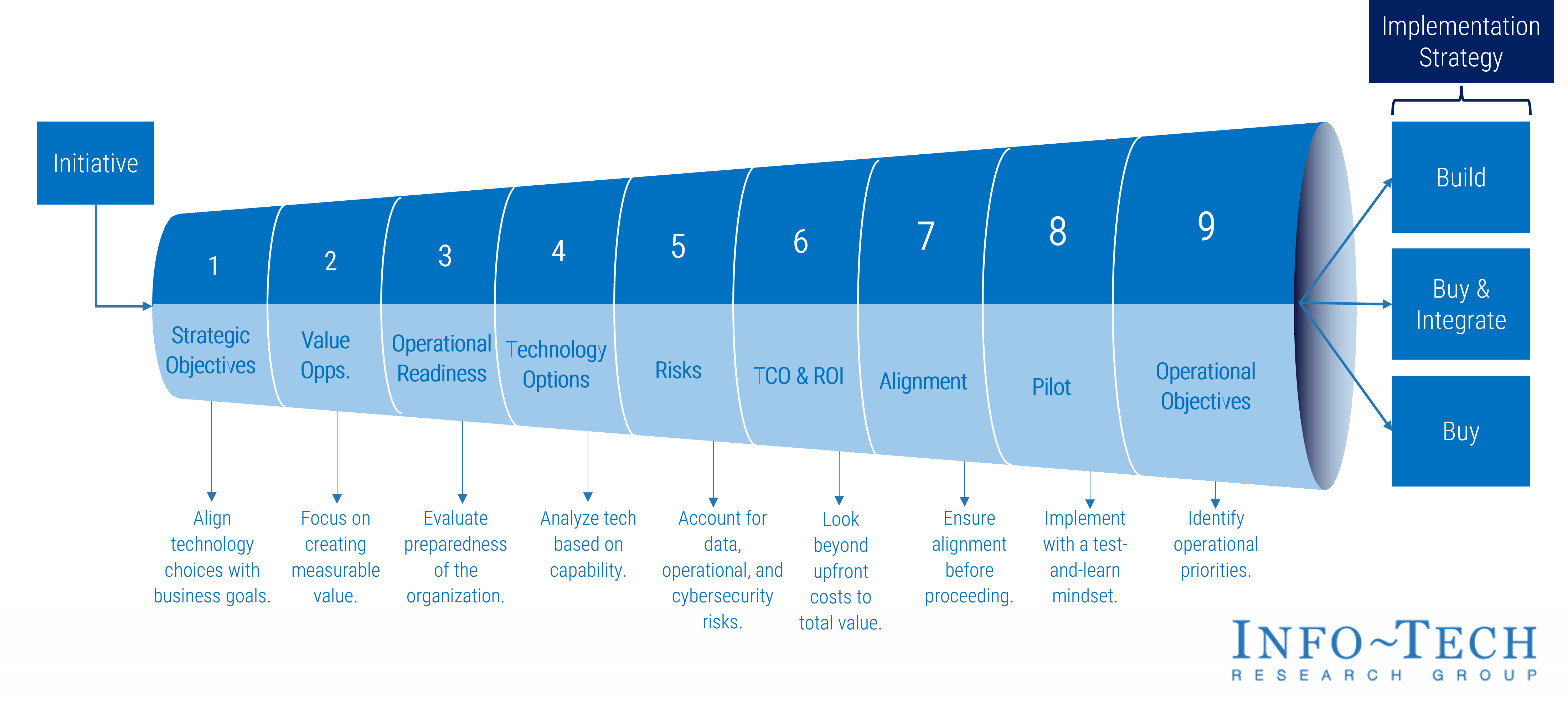

- Strategy

CIOs must establish clear, organization-wide strategic objectives. - Value

CIOs must identify specific use cases where connected technologies can create meaningful value. - Readiness

CIOs must assess whether the people, processes, and infrastructure are in place. - Technology

CIOs must evaluate the available technology solutions. - Risks

CIOs must conduct a comprehensive risk and cybersecurity analysis before deployment. - ROI

CIOs must evaluate both the TCO and the ROI. - Alignment

CIOs must engage all relevant internal stakeholders early. - Pilots

CIOs must use pilots to validate assumptions, mitigate risks, and build a blueprint for scaling.

CIOs have a key role in ensuring that connected technologies continue to align with broader organizational goals. Their current level of connected technology awareness will decide how they build a connected technology strategy and what problems they should solve for.

Info-Tech offers various levels of support to best suit your needs

DIY Toolkit | Guided Implementation | Workshop | Consulting |

| “Our team has already made this critical project a priority, and we have the time and capability, but some guidance along the way would be helpful.” | “Our team knows that we need to fix a process, but we need assistance to determine where to focus. Some check-ins along the way would help keep us on track.” | “We need to hit the ground running and get this project kicked off immediately. Our team has the ability to take this over once we get a framework and strategy in place.” | “Our team does not have the time or the knowledge to take this project on. We need assistance through the entirety of this project.” |

Diagnostics and consistent frameworks are used throughout all four options. | |||

Guided Implementation

A Guided Implementation (GI) is a series of calls with an Info-Tech analyst to help implement our best practices in your organization.

A typical GI is 4 to 8 calls over the course of 4 to 6 months.

Take the right actions to advance the smart factory agenda.

Phase 1 | Phase 2 | Phase 3 | Phase 4 |

| Call #1: Understand prerequisite concepts – IT/OT convergence. Call #2: Understand prerequisite concepts – OT visibility and cybersecurity. | Call #3: Assess current capabilities. Call #4: Understand the potential of connected technologies. | Call #5: Discuss organizational objectives. Call #6: Conduct technology/ use case selection exercise. | Call #7: Debrief session; gather program feedback. |

Workshop Overview

Contact your account representative for more information.

workshops@infotech.com 1-888-670-8889

Day 1 | Day 2 | Day 3 | Day 4 | Day 5 | |

Identify Your Current State Governance | Define the IT Target State | Assess the IT Current State | Bridge the Gap and Create the Strategy | Next Steps and Wrap-Up (offsite) | |

Activities |

|

|

|

|

|

Deliverables |

|

|

|

|

|

Text – Facilitated group exercises Text – Facilitated information sharing

The case for connected technologies

Why you should care.

Connected technologies are seeing adoption across a range of industries

Connected technologies are being adopted across a wide range of industries – from manufacturing and logistics to healthcare and energy – driven by the need for real-time insights, automation, and improved decision-making. These technologies enable organizations to optimize operations, enhance safety, and unlock new business models, making them foundational to digital transformation.

Manufacturing | Real-time insights improve production efficiency. | Logistics | Drones use IIoT for faster deliveries. | Agriculture | Automated tractors optimize farming processes. | Automotive | IIoT drives autonomous vehicle advancements. | Transportation | Sensors optimize routes, prevent spoilage. | Power | IIoT simplifies power grids, automates systems. | Construction | IIoT monitors equipment, ensures safety compliance. |

The convergence of IT and OT is redefining manufacturing operations

CIOs should ensure the nuances of IT modernization, OT modernization, and IT/OT convergence are understood by all decision-makers. These interconnected concepts offer distinct pathways to enhance operational efficiency and business agility, and it is imperative to understand their individual and combined contributions.

Improve efficiency, agility, scalability, and security

IT Modernization

The process of updating and enhancing an organization's IT infrastructure, software applications, data management systems, and related processes.- Transition from on-premises to cloud solutions.

- Adoption of modern software practices.

- Enhanced cybersecurity measures.

Drive digital transformation and holistic operational visibility

IT/OT Convergence

The integration and alignment of IT and OT systems and processes to create a unified, interconnected environment.- Bridging the gap between business IT systems and operational technologies.

- Seamless flow of data across the organization.

- Better decision-making and optimization.

Enhance operational efficiency, safety, and productivity

OT Modernization

The updating of technology and systems used to monitor and control physical devices and processes in industries.- Integration of IoT devices.

- Advanced analytics for real-time insights.

- Seamless machine-to-machine communication.

Manufacturers have begun making bold investments in connected technologies

Connected technology investments have benefited from advancements in network connectivity, cloud services, edge hardware, and maturing security standards. This, along with widespread awareness of the benefits of connected technologies have spurred manufacturers to action.

According to Microsoft’s Digital Operations Signals Survey:

- Projects have become more successful.

- Time to break even has decreased sharply.

- Companies are faster to develop the business case.

- Adoption of “off-the-shelf” solutions are on the rise.

- Implementation is becoming less challenging.

Connected technology adoption has reached the mainstream majority. Manufacturers that are still dealing with challenges relating to legacy systems, processes, data management, and privacy will get left behind.

CIOs will have a critical role to play in advancing the agenda.

Connected technologies are becoming mainstream.

- 95% of manufacturers are using or evaluating smart manufacturing technology.

- 65% of manufacturers are now executing an IIoT strategy.

- 43% of recent projects have exceeded expectations.

- 50% reduction in challenges related to project complexity and data prerequisites.

(Source(s): 9th Annual State of Smart Manufacturing, Rockwell Automation, 2024, Digital Operations Signals, Microsoft, 2023)

Connected technologies make manufacturing more intelligent, automated, integrated and visible

- Manufacturing Execution Systems provide real-time production management to drive enterprise-wide compliance, quality, and efficiency.

- Distributed Control Systems use decentralized elements to control dispersed systems, machines, and/or equipment.

- Computerized Maintenance Management Systems (CMMS) helps track and manage maintenance activities for facilities, equipment, and other assets.

- Asset Management combines process, machine, and operations data to monitor machine health.

- Power Control Devices manage transfer of power from the source to various applications.

- Industrial Control Systems are responsible for processes and quality compliance.

- Smart Devices are digital assets that acquire, process, and monitor operations data.

- Robotics enable automated operations with full/partial autonomy.

- Analytics uses data to optimize operations, remove bottlenecks, and provide new insights.

- Material Management orchestrates material flow through the production line.

- Quality Management Systems automates quality documentation, processes, and measurements.

- S&OP matches demand and supply forecasting with inventory accuracy and production scheduling.

- Production Monitoring provides connectivity to machines and visibility to KPIs like OEE.

Text – Covered in this research

(Source: 9th Annual State of Smart Manufacturing, Rockwell Automation, 2024)

Connected technologies bring proven benefits to manufacturers

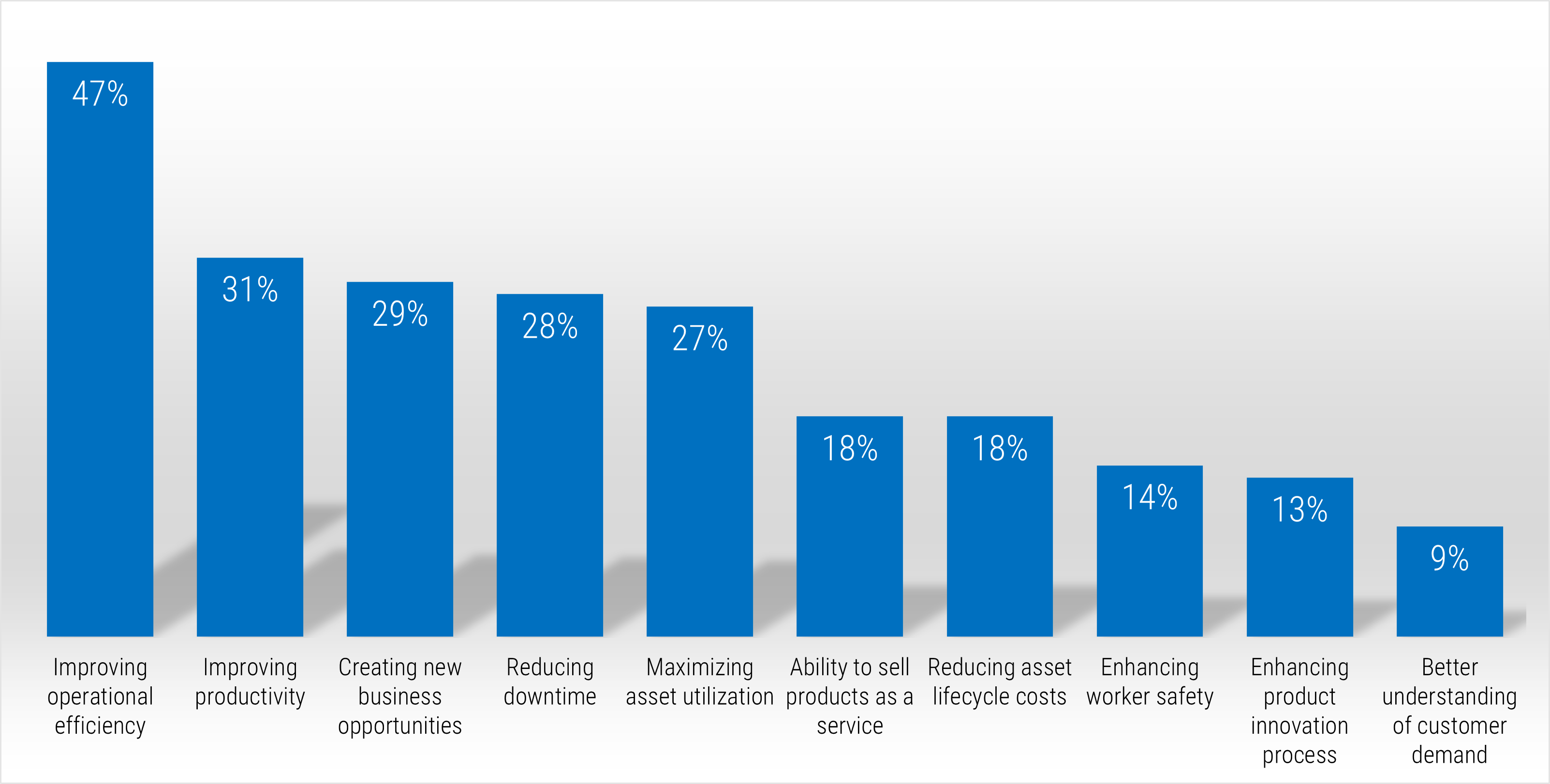

Connected technologies offer manufacturers real-time visibility, data-driven insights, and automation capabilities that improve efficiency, quality, and responsiveness. By linking machines, systems, and people, they enable smarter decision-making and unlock new opportunities for innovation and growth.

(Source: The Internet of Things and the New Industrial Revolution, Morgan Stanley, 2016)

Investments in connected technologies increases the rate of growth, innovation, and efficiency for manufacturers.

“As a result of investing in use cases surrounding operational intelligence, asset optimization, and workforce productivity, we’ve seen…customers cut operational costs by 12%, while boosting operator productivity by up to 60%.” (Source: The Benefits of IoT in Manufacturing, PTC, 2020)