Develop a business-driven AI strategy to improve inventory management that minimizes the risks associated with an AI-based solution.

Understand the potential opportunities and risks to improving business outcomes and best practices when developing or deploying an AI-driven inventory management application.

Assess the organization’s capabilities to provide a data platform that is optimized for analytics and inventory management and would support new technology infrastructure.

Our Advice

Critical Insight

An AI-driven inventory management system is needed to stay competitive where competitors are putting pressure on the retail industry by adopting and utilizing AI to run the core operations of their organizations.

Impact and Result

Guide business leaders through identifying and prioritizing AI use cases for their business capabilities through a benefits realization model to start their AI journey.

Leverage the output to gain executive buy-in to rapidly and responsibly implement AI, referencing use cases that can provide the greatest value to address your organizational challenges and meet business goals.

Develop an AI strategy use case roadmap for retail inventory management that becomes a strategic path forward that effectively and efficiently accelerates adoption.

Build Your AI Strategy for Retail Inventory Management

Identify value-driven AI strategy use cases to transform your inventory management.

Analyst perspective

Implement value-driven AI use cases responsibly.

In today's competitive retail landscape, retailers are feeling the pressure to optimize their inventory management practice. With fluctuating customer demand, fast-paced market disruptions, complex supply chains, and rising costs, traditional inventory management practices are becoming increasingly inadequate. To stay competitive, retailers must embrace and implement new technology that allows them to stay ahead of the competition.

Inventory management applications that are AI-driven can deliver where traditional inventory management falls short, by providing real-time insights backed by big data, enabling retailers to respond to market changes through predictive forecasts that reduce waste, improve operational efficiency, and enhance customer satisfaction.

While most retailers understand the potential of AI, most lack the clarity of where to start, what to adopt, and how to scale, to take advantage of the competitive edge that AI provides. This research piece provides clarity around AI in inventory management and use cases and offers a step-by-step guide to help retailers build out a robust and actionable AI use case library for inventory management.

Donnafay MacDonald

Research Director, Retail Industry Practice

Info-Tech Research Group

Executive summary

Your Challenge

Develop a business-driven AI strategy to improve inventory management that minimizes the risks associated with an AI-based solution.

Understand the potential opportunities and risks to improving business outcomes and best practices when developing or deploying an AI-driven inventory management application.

Assess the organization's capabilities to provide a data platform that is optimized for analytics and inventory management and would support new technology infrastructure.

Common Obstacles

Getting the right business stakeholders together to develop an AI strategy that addresses inventory management limitations and understands the gaps the organization needs to address to fully leverage AI.

Prepare and understand the benefits associated with AI, which often requires mature data and system capabilities.

Advancing existing business and human-based requirements to adopt AI-driven applications.

Info-Tech's Approach

Guide business leaders through identifying and prioritizing AI use cases for their business capabilities through a benefits realization model to start their AI journey.

Leverage the output to gain executive buy-in to rapidly and responsibly implement AI, referencing use cases that can provide the greatest value to address your organizational challenges and meet business goals.

Develop an AI strategy use case roadmap for retail inventory management that becomes a strategic path forward that effectively and efficiently accelerates adoption.

Info-Tech Insight

Retailers need to adopt an AI-driven inventory management system to stay competitive in an industry where competitors are using AI to run the core operations of their organizations.

It is essential to mitigate the challenges of traditional inventory management

Traditional inventory management practices in retail have limitations and primarily focus on two key parameters: (1) the process of ordering product, and (2) carrying buffer stock to meet demand. In addition, the management systems used are often restrictive with low product visibility, limited flexibility, and lack of robust data analytics. This leads to inefficient operations and higher costs of doing business.

Retailers often misjudge product demand due to the use of disparate systems in complex supply chains which adds the challenge of working with fragmented data in outdated tools, such as Excel, leading to inaccurate forecasts, missed sales opportunities, dissatisfied customers, and unnecessary costs to the organization.

The underlying challenge is the rigidity of traditional inventory management where it is unable to adapt quickly to changes in sudden market shifts, unexpected disruptions, and changes to trends and customer behavior. Ultimately, the challenges of traditional inventory management practices leaves retailers less competitive.

"In the intricate world of business operations, mastering inventory control is not just a necessity – it's the key to unlocking operational excellence."

Source: Supply Chain 24/7, 2024.

Traditional Inventory Management Challenges

- Lack of Visibility

- Lack of Data Analytics

- Integration Issues

- Lack of Flexibility

- Complexity

- Overstocking and Understocking

Misjudged product demand increases retailer losses

"Forecasting accuracy is a crucial factor for any business that relies on predictions of future events, such as demand, sales, revenue, costs, risks, or opportunities."

Source: FasterCapital, 2024.

|

Lost Customers |

Lost Global Revenue |

Increased Cost |

|---|---|---|

|

91% |

8.3% |

43% |

|

of consumers will choose not to shop with a retailer after a negative experience. |

of global retail revenue is lost due to out-of-stock items, amounting to an estimated $1.75 trillion annually. |

of retailers face increased costs in the supply chain because of stockouts. |

Source: Tools Group, 2024.

Lead with value by aligning AI initiatives to business needs

"AI projects should come from a value-led position rather than being led by technology. The key is to always ensure you know what value you're bringing to the business or to the customer with the AI."

– Alex Sidgreaves, Chief Data Officer at Zurich Insurance, quoted in MIT Technology Review, 2024

|

Leverage AI to Enhance Operations |

Improve Inventory Management With AI |

|---|---|

|

51% |

72% |

|

of retail and consumer package goods executives state they are using AI in their operations. |

of AI implementations in physical stores is being used for inventory management. |

AI overview

Definitions

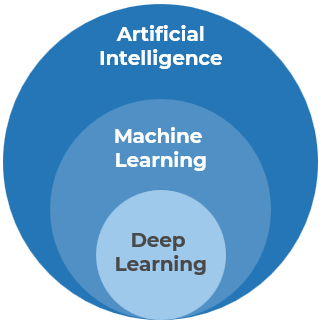

Artificial intelligence (AI) is human intelligence mimicked by machine algorithms. Examples: playing chess or Go.

Machine learning (ML) is a subset of AI algorithms to parse data, learn from data, and then make a determination or prediction. Example: spam detection, preventative maintenance.

Deep learning (DL) is a subset of machine learning algorithms that leverage artificial neural networks to develop relationships among the data. Examples: image classification, facial recognition, generative AI.

What Makes AI Perform

Algorithms

Accelerators

Big Data

What Makes AI Different

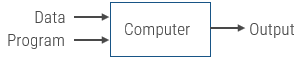

|

Traditional Programming |

Machine Learning |

|---|---|

|

|

Design value-driven outcomes with an AI strategy for inventory management

Building out an AI strategy for retail inventory management involves linking AI capabilities to the strategic sources of value of the retail organization. AI adoption should focus not only on technology adoption but also on what real business problems are being solved and the value being created. Below is a list of the strategic sources of value and operational sources of value to consider when building out your AI strategy for retail inventory management.

Retailers adopting AI in inventory and supply chain management have seen up to 48% optimization gains.

Source: Nvidia, 2025

|

Strategic Sources of Value |

Description |

|---|---|

|

Operations Efficiency |

Reducing costs through operational performance improvements. |

|

Customer Experience |

Improving customer experience with a product/service through reliability, engagement, transparency, etc. |

|

Business Growth |

Expanding the organization's products/services/ capabilities to ultimately drive revenue expansion or customer impact. |

|

Employee Experience |

Optimizing the employee experience through changes that make work easier and more enjoyable, thus increasing job satisfaction. |

|

Risk & Resilience |

Mitigating diverse risk, health, safety, and continuity of operations concerns to preserve stable and sustainable performance. |

|

Environment, Social & Governance (ESG) |

Improving environmental impacts, social and community wellbeing, and corporate governance practices. |

|

Operational Value Outcomes |

Description |

|---|---|

|

Reduced Costs, Waste, and Spoilage |

AI-powered forecasting, allocation, and replenishments reduce overstock, spoilage, and obsolescence. |

|

Improved Profit Margins |

Precise inventory management and data-driven product allocations improves overall inventory position. |

|

Increased Operational Efficiency |

Streamlined supply chain using AI and automation leads to efficient operations and faster inventory turns. |

|

Faster Response to Market Changes |

Real-time date and predictive insights helps retailers quickly adjust and adapt inventory strategies. |

|

Improved Supplier Relationships |

Informed AI-driven demand forecasts allows for more reliable planning, fostering stronger partnerships and better inventory. |

|

Enhanced Customer Satisfaction |

AI-driven product allocation ensures the right product is available at the right time. |

Value outcomes from AI-driven inventory management applications

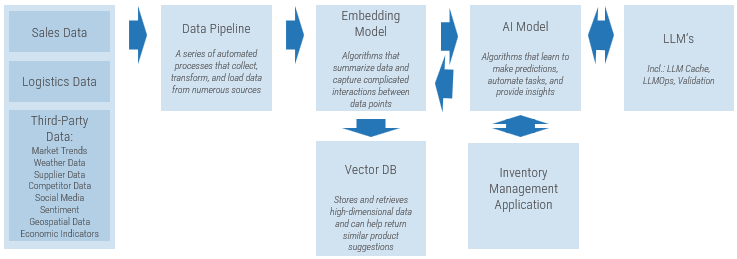

Visual representation of an AI inventory management data and decision-making flow

Value Outcomes

- Reduced Costs, Waste, and Spoilage

- Increased Operational Efficiency

- Improved Supplier Relationships

- Improved Profit Margins

- Faster Response to Market Changes

- Enhanced Customer Satisfaction

"Without proper tools and processes for managing data, enterprises will find themselves at a severe disadvantage in an AI-first economy that is fueled by data. A seamless, end-to-end analytics platform empowers procurement and supply chain with AI-driven insights, centralized data management and self-service capabilities, unlocking agility, cost efficiency and informed decision-making."

Source: GEP Intelligence, 2024

Source: LeewayHertz, 2025

Maximize retail success through effective inventory management principles

|

Principles |

Summary |

Advantages |

Disadvantages |

Uses |

|

Just-in-Time Inventory (JIT) |

Aims to increase inventory efficiency while decreasing waste by receiving goods only when they are needed in the process |

Reduction in waste, improved efficiency, greater productivity, smooth production flow, lower costs |

Supply chain disruptions and order issues will impede the business; overreliance on forecasts; supplier dependence to deliver on time |

Items that expire, manufacturing, etc. |

|

Economic Order Quantity (EOQ) |

Determines what the optimal order quantity needs to be to minimize total inventory costs including holding costs and ordering costs |

Cash flow tool, can identify the reorder point, encourages volume orders vs. many small orders |

Assumes steady demand, ignores seasonal or economic fluctuations |

Stable and consistent situations |

|

Materials Requirement Planning (MRP) |

Uses detailed sales forecasts to order materials needed to produce finished items |

Improved inventory control with optimized scheduling, cost reductions, increased efficiencies |

Relies heavily on data and accurate forecasts, rigid planning with high complexity |

Manufacturing goods |

|

First-in-First-Out (FIFO) |

Accounting principle that assumes oldest inventory is sold first and remaining inventory consists of newest product |

Minimize loss due to expiry dates, easy to implement and difficult to manipulate or embellish company financials, best reflects current value of inventory |

Can overstate profits, inventory may not be truly reflected in innovative industries where product can become obsolete due to new technology, trends, and innovation |

Perishable goods |

|

Last-in-First-Out (LIFO) |

Accounting principle that assumes newest inventory is sold first and remaining inventory consists of oldest product |

Can lower taxable income that leads to higher cash flow, important when expenses are rising, |

Ending inventory value may be understated, banned under international financial reporting standards as it minimizes taxable income |

Companies that maintain large and costly inventories |

|

Days Sales of Inventory (DSI) |

Average time in days that it takes a company to turn its inventory. A financial ratio that indicates how many days current inventory will last before being replenished |

Shows how effectively inventory is being managed, high DSI can indicate a problem with inventory and trigger a remedial action |

Lacks context if used as a standalone metric, does not consider seasonal fluctuations |

All retailers as an effective inventory management metric |

|

Safety Stock |

Safety stock is inventory that is kept on hand to cover unexpected demand or supply chain disruptions |

Safeguards against lost sales due to supplier disruptions, inaccurate forecasts, and/or market volatility |

Excess inventory increasing costs |

Good for unpredictable demand |

|

ABC Analysis |

Grading that group's inventory into three categories (A, B & C) based on the level of importance of the inventory |

Optimized inventory, improved forecasting, better pricing on growth product, improved stock turnover rate, reduced costs |

Ignores seasonal fluctuations, high-level view on inventory grouped together in B & C, arbitrary categorization, high resource consumption |

Good for large organizations |

Sources: Issues Up Solutions, 2024; Investopedia, 2024.

*A representation of principles, data, and value outcomes; not an exhaustive list

Leverage AI-driven inventory management principles to achieve value outcomes

|

Principles |

Solve for |

AI Opportunities |

Key Data Points |

Reduced Costs, Waste, and Spoilage |

Improved Profit Margins |

Increased Operational Efficiency |

Faster Response to Market Changes |

Improved Supplier Relationships |

Enhanced Customer Satisfaction |

|---|---|---|---|---|---|---|---|---|---|

|

Just-in-Time Inventory (JIT) |

Over or under stocking; inefficient coordination in the supply chain |

Assist in optimizing deliveries and supply chain coordination through real-time AI-powered algorithms that generate demand forecasts and analyze inventory in real time |

Sales history, market trends, lead time, supplier reliability, inventory (from IoT, RFID etc.) |

✔ |

✔ |

✔ |

✔ |

✔ |

✔ |

|

Economic Order Quantity (EOQ) |

Optimize order quantities; minimize carrying costs |

Dynamically adjust order quantities based on real-time data analysis |

Sales & order history, lead times, holding cost per unit |

✔ |

✔ |

✔ |

✔ |

||

|

Materials Requirement Planning (MRP) |

Align material purchases and production needs |

Enhance material planning by predicting demand and optimizing orders |

Sales history, production schedule, bill of materials, supplier performance |

✔ |

✔ |

✔ |

✔ |

✔ |

✔ |

|

First-in-First-Out (FIFO) |

Ensure oldest stock is sold first |

Automate stock rotation and ensure accurate tracking of product age |

Sales velocity, product shelf life, expiry dates |

✔ |

✔ |

✔ |

✔ |

||

|

Last-in-First-Out (LIFO) |

Ensure newest stock is sold first |

Automate stock rotation and track inventory for more accurate reporting |

Purchase date, sales velocity, cost of goods |

✔ |

✔ |

||||

|

Days Sales of Inventory (DSI) |

Track inventory turn rate and stock efficiency |

Provide real-time monitoring and actionable insights into increasing turnover rates |

Sales history, inventory position, order frequency, market trends |

✔ |

✔ |

✔ |

|||

|

Safety Stock |

Calculate and maintain optimal safety stock |

Predict demand and possible disruptions to optimize safety stock levels |

Sales history, inventory position, supplier reliability, demand variability |

✔ |

✔ |

✔ |

✔ |

✔ |

✔ |

|

ABC Analysis |

Classify inventory items in the most meaningful way |

Automate categorization and continuously update stock categories |

Sales history, turnover rates, profit margins, inventory position |

✔ |

✔ |

✔ |

✔ |

✔ |

✔ |

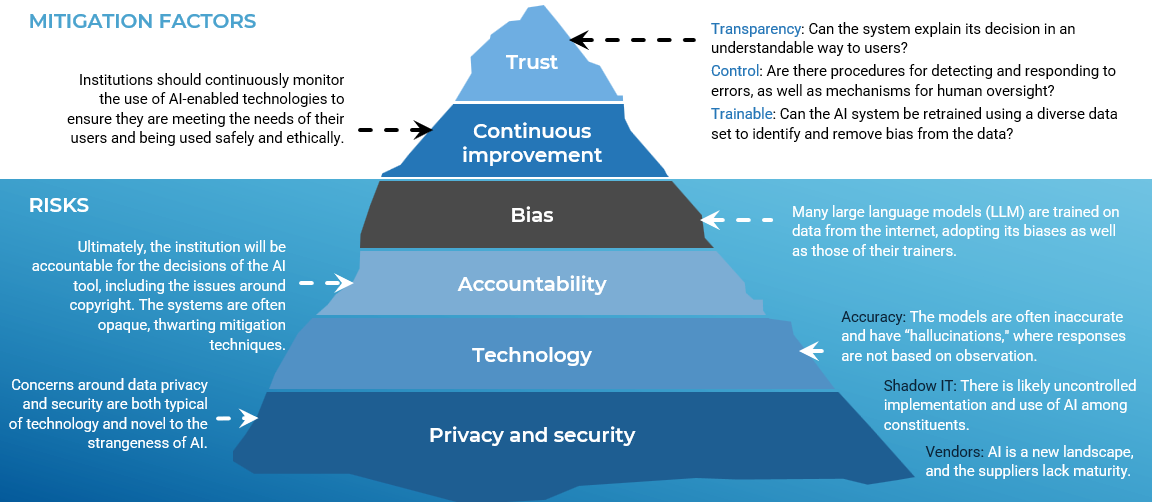

Consider the risks of AI

There are more than the usual number of risks with AI technology.

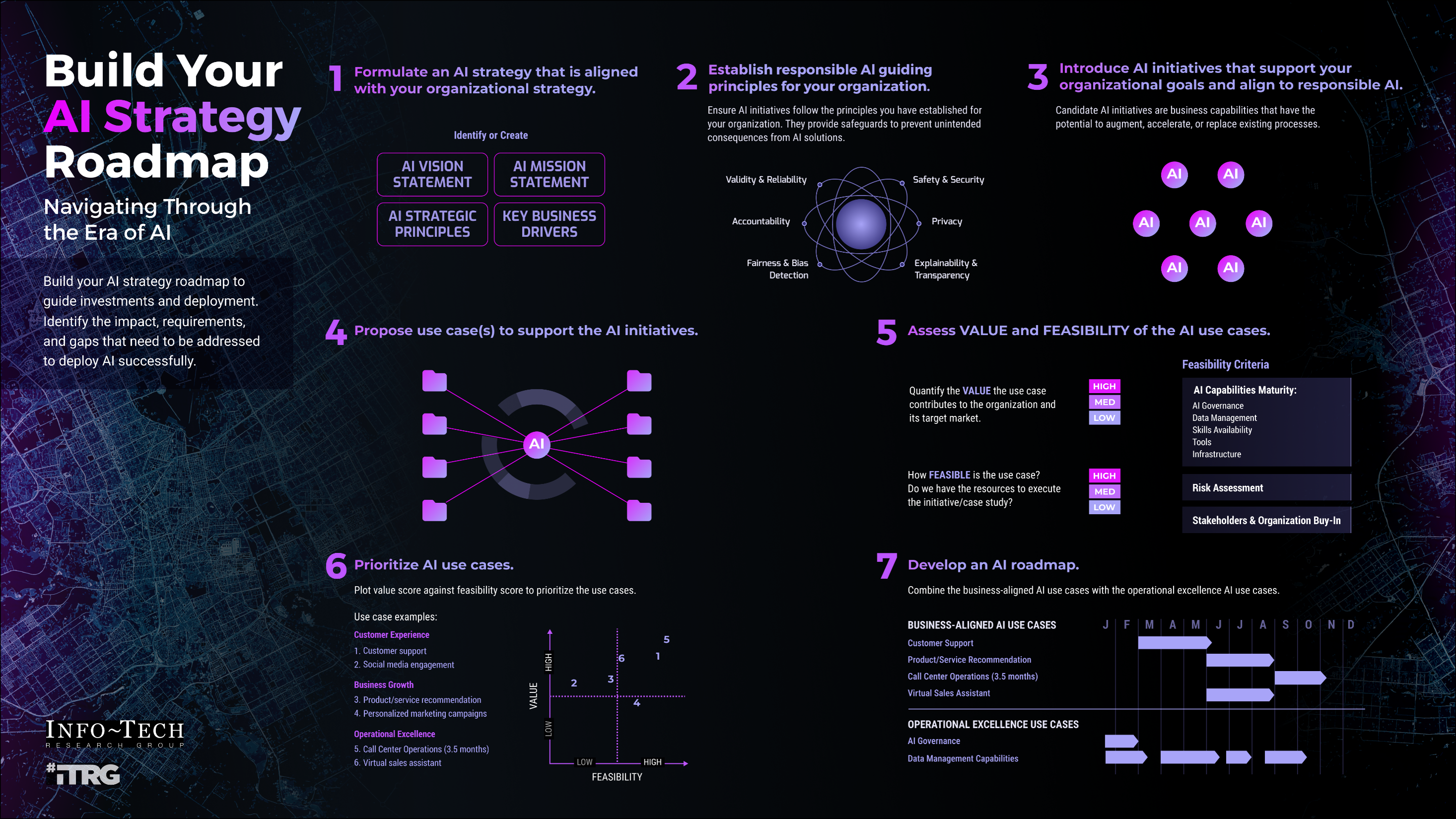

Building your AI strategy use case library for inventory management

What Is Known

- AI has the power to transform how inventory is managed.

- Leveraging AI can reduce excess inventory and optimize stock.

Actions To Take

- Identify areas within the inventory management process where AI can provide the most impact – Step 4 in Build Your AI Strategy Roadmap.

- Systemically build your AI use case library for inventory management based on the value proposition and feasibility of each use case – Step 5 in Build Your AI Strategy Roadmap.

- Prioritize and build a structured path toward adopting AI in inventory management – Step 6 in Build Your AI Strategy Roadmap.

"Achieving high levels of forecasting accuracy is not easy, as it depends on many factors, such as the quality and availability of data, the choice and suitability of forecasting methods, the skill and experience of forecasters, and the alignment and communication of forecasts across the organization."

Source: FasterCapital, 2024

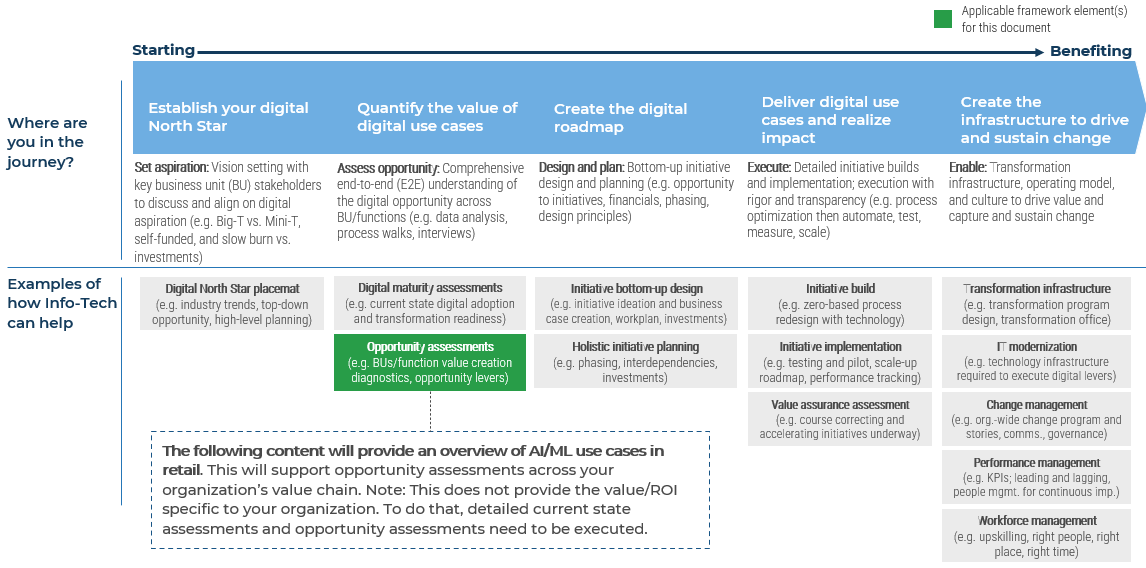

Info-Tech's approach and team can help, irrespective of where you are in your digital journey

How to use this report

Visit Info-Tech's Build Your AI Strategy Roadmap blueprint for full activity details

Use this map to determine where to use this research material.

This report is designed to complement Info-Tech's comprehensive Build Your AI Strategy Roadmap blueprint and associated activities. It uses research-based data for "ACME Corp Data" to demonstrate AI use case opportunities for use in a holistic AI strategy and roadmap. Once you have completed the activities within this report, return to the core research to progress through the remaining phases of the broader strategy.

Realize all teams are unique and you may feel that some sample information may not be relevant to or represent your organization well due to the different type of products and services you are engaged in, geographic area you're located in, etc. We recommend that you adjust and customize the template as needed to be organization-specific and to create the most valuable AI strategy for your organization.

You will use this report as a research-based accelerant input as you work through phases 2 and 3 and activities 2.1 and 3.1 of Build Your AI Strategy Roadmap blueprint, specifically:

|

AI strategy roadmap activities |

|

|---|---|

Phase 2 |

Phase 3 |

|

Identify AI Use Cases |

Prioritize AI Use Cases |

|

Activity 2.1 Map your candidate AI use cases |

Activity 3.1 Prioritize candidate AI use cases |

Measure the value of this document

Document your objective

Highlight best-in-class use cases to spur the initiative-planning and ideation process.

Measure your success against that objective

There are multiple qualitative and quantitative, direct and indirect metrics by which you can measure the progress of your initiative pipeline's development. Some examples are:

- Increased initiative pipeline value

- Number of capabilities impacted by initiative pipeline

- Enhanced understanding of the initiatives' impact aligned to the organization's capability map

- Better understanding of which sources of value are being addressed or under-addressed in the organization's initiative pipeline

See Establish Your Digital Transformation Governancein the Digital Transformation Center for more details

AI in retail inventory management aims to produce measurable results

Operational Value Outcomes | Metrics | Impacts | Measures |

|---|---|---|---|

Reduced Costs, Waste, and Spoilage | Inventory carry costs, shrink rates, spoilage percentages | Lower storage costs, reduced, expired, or unsold inventory | Shrink rates and carrying costs |

Improved Profit Margins | Order cycle time, inventory turns, warehouse processing time | Streamline operations, fewer errors, faster replenishment | Turnover ratios, lead time |

Increased Operational Efficiency | Gross margin, profit per SKU, operating cost percentages | Higher profitability, reduced markdowns, optimized pricing | Gross margin percentages |

Faster Response to Market Changes | Time to replenish, stock availability, inventory turns | Ability to adapt to market shifts and demand changes | Allocation and replenishment response time, stock availability |

Improved Supplier Relationships | Supplier lead times, on-time delivery rate, order accuracy | Stronger supplier relationships, improved trust | On-time delivery metrics, supplier satisfaction scores |

Enhanced Customer Satisfaction | Customer satisfaction scores (CSAT), net promoter score (NPS), order fulfilment rates | Increased customer loyalty, customer retention through repeat purchases | CSAT, NPS, reduced returns |