Global supply chain uncertainty has upended the manufacturing sector. CIOs and their teams find themselves on the front lines of this disruption. Facing a dual mandate, they’ve been tasked with slashing costs while simultaneously enabling advanced capabilities such as automation and AI. Our step-by-step blueprint can help forward-looking IT leaders build a Technology-First Action Plan optimized for manufacturers to turn today’s volatility into tomorrow’s value.

It's not enough to respond to shocks as they come – CIOs must build responsiveness and intelligence into their organization’s IT operations, allowing them to anticipate and rapidly respond to disruption. This posture of IT resilience not only allows IT to drive innovation within the organization but also positions it as a trusted leader at the highest levels.

1. Cut costs to free up resources for innovation.

Innovation drives new ways of generating organizational value but often sees its budget slashed amid budget constraints. IT leaders must cut unnecessary costs and redirect that spending to the people, resources, and budgetary capacity their innovation efforts will need to overcome today’s turmoil.

2. Meet the moment. Take the lead.

As much as today’s uncertainty is a strain on IT’s resources, it can also be an opportunity. By demonstrating that their technological know-how can be used not only to solve problems but also to enable better decision-making, CIOs can prove their ability to lead not just IT, but the organization as a whole.

3. Build an adaptive IT team.

With technology advancing at an exponential rate, organizations will never permanently close the skills gap. By focusing instead on building sustainable learning and development practices, CIOs can enable their staff to retain knowledge and develop in-demand skills as they are needed.

Use this step-by-step blueprint to realign IT to lead through manufacturing disruption

Our research offers guidance and templates to clearly assess IT’s strengths and vulnerabilities and where they can be leveraged. Use our Technology-First Action Plan framework to empower IT to lead their organization through today’s manufacturing challenges.

- Assess uncertainties and opportunities by leveraging this moment to explore where the organization is most vulnerable and where it is most poised to further lean into technology risks.

- Review IT Spend & Staffing tools and services to find costs that can be either cut or channelled toward innovation opportunities.

- Build your Technology-First Action Plan by identifying and prioritizing initiatives that will drive the organization forward and consolidate those initiatives into a 12-month plan.

- Prepare to execute by defining the organizational value of your plan and building an adjustable communications strategy to bring stakeholders on board.

Adapt to Uncertainty With a Technology-First Action Plan for Manufacturing

Respond faster, operate smarter, and adapt continuously in the face of constant change.

Analyst perspective

Respond faster, operate smarter, and adapt continuously in the face of constant change.

CIOs must confront a dual reality. On one side, they are expected to reduce spending, consolidate systems, and justify every investment. On the other, they must support new demands for digital automation, data-driven operations, cybersecurity, and remote collaboration. Many manufacturers are ill-suited to respond to fast-changing conditions. Technical debt, lack of interoperability, and brittle workflows threaten to compromise operational continuity. While cost-cutting remains a reflexive response, forward-looking CIOs recognize that technology, when deployed strategically, is a critical enabler of resilience. The ability to weather disruption and emerge stronger now hinges on how well IT supports core operations, decision-making agility, and long-term adaptability.

This research explores how manufacturing CIOs can use the concept of IT resilience as a framework for strategic action. CIOs must be able to anticipate disruption, absorb shocks, reconfigure resources, and enable the business to pivot at speed. Resilient IT systems enable organizations not only to survive turbulence but to gain advantage through it.

We present a practical IT resilience action plan that aligns with the specific operational realities of manufacturing. This includes clear guidance on stabilizing infrastructure, protecting digital assets, prioritizing investments that unlock operational flexibility, and identifying areas where automation and digital insight can reduce cost while improving throughput and quality. The goal is to build responsiveness and intelligence into the digital core of the business and to position IT not just as a support function but as a key driver of operational confidence and business innovation.

Let us help you build a technology-first action plan that can turn today’s volatility into tomorrow’s value.

Shreyas Shukla

Research Director, Manufacturing

Info-Tech Research Group

Please note: This research was developed with the assistance of generative AI. For information about how, please see in the Appendix

Executive summary

Manufacturers face a defining moment of disruption

Factory activity in contraction: The Institute for Supply Management (ISM) manufacturing Purchasing Managers’ Index (PMI) fell from 48.7 in April to 48.5 in May, marking the third consecutive month of contraction. 1

Slowest supplier deliveries since 2022: The ISM’s supplier deliveries index surged to 56.1, its highest since 2022, compared with 55.2 the previous month, signaling longer lead times driven by tariff disruptions. 2

Decline in imports and exports: The ISM reported an imports index of just 39.9, the lowest since early 2009, while exports also contracted, reflecting weakened global trade flows. 2

Rising inventories and low orders: Manufacturers have stockpiled inventories to their highest level since the pandemic even as new orders remained subdued at a PMI sub-index of 47.6. 3

Falling employment: The manufacturing employment sub-index dropped to 46.8 from 46.5 in April, indicating seasonal job cuts amid growing uncertainty. 4

Pressures on pricing: The PMI’s input prices index eased slightly to 69.4 from 69.8 but are still well above 50, highlighting continued stress from rising input costs. 2

Info-Tech Insight

Manufacturers are under pressure as external shocks multiply.

Survival is not a strategy.

Now is the time to act, with a Technology-First Action Plan built for manufacturing.

That’s why we’ve tailored this blueprint and the accompanying sample deliverable specifically for the manufacturing industry.

1. Trading Economics

2. Reuters, 2025

3. US Manufacturing Report, 2025

4. The Business Times, 2025

Executive summary

Your challenge

Manufacturers are reeling from external shocks that will fundamentally reshape how they operate

Global supply chain disruption and supply re-shoring

Manufacturers continue to grapple with unacceptable lead times resulting from external pressures on supply chains. Geopolitical instability, increasing costs, and regulatory complexity pose immense risk to procurement, logistics, and compliance. Research says that “63% of companies are conducting supply chain risk assessments with price impact analysis.”1

CIOs will be called upon to address demand for supply chain visibility, and risk analytics tools to manage uncertainties effectively.

Volatile energy markets and rising input costs

Manufacturers are facing sustained energy price volatility. Unstable energy costs, high industrial tariffs, and a lack of subsidies are causing profit erosion, delayed capital investment, and increased vulnerability to policy shifts. For instance, “UK industrial energy costs are now twice those of Europe and four times those in the US, and manufacturers face no new relief initiatives.”2

For CIOs, this necessitates tighter integration of IT and operational technology (OT) systems to track energy consumption and support energy management platforms.

Talent shortage and skills gaps

Manufacturers are struggling with skills gaps, an aging workforce, negative perception, and rising cost of hiring domestically. Labor shortages remain a top concern in 2025, with both skilled trades and digital talent in short supply. According to research, “Manufacturers have averaged about 500,000 open jobs every month for several years now.”3

CIOs will need to respond by investing in automation, knowledge capture, and low-code/no-code platforms.

1. CAPS Research, 2025

2. “No New Money,” Financial Times, 2025

3. “Companies Are Struggling,” Business Insider, 2025

Executive summary

Common obstacles

For CIOs and IT leaders, these vulnerabilities present challenges to achieving their technology mandates

Capital constraints and cost pressure

Manufacturers are delaying or downsizing digital and infrastructure investments amid persistent inflation, high interest rates, and market uncertainty. Organizations have instituted spending freezes or mandated double-digit cuts to technology budgets, even as operational complexity increases. “The Institute for Supply Management (ISM) expects a 1.3% decrease in capital expenditure this year.”1

For CIOs, this creates a constant tradeoff between short-term survival and long-term transformation, with limited room to modernize core systems or fund high-impact digital programs.

Fragmented and legacy technology environments

Decades of incremental IT investments have left many manufacturers with siloed, aging systems that are difficult to integrate, scale, or secure. New retooling or replatforming efforts will require deep pockets. “Many factories still operate with shop-floor software and hardware that lack compatibility and are 30, 40, or even 50 years old.”2

This fragmentation places a heavy burden on CIOs, who must architect transitional pathways while ensuring operational continuity.

Regulatory complexity and policy uncertainty

Manufacturers operating across borders face an increasingly complex regulatory environment, including divergent data privacy laws, trade restrictions, cyber regulations, and environmental, social, and governance (ESG) mandates. PWC found that “nearly 90% of organizations feel that increasing complexity of compliance requirements impacts implementing and maintaining IT systems and data.”3

For CIOs, this makes long-term planning more difficult and necessitates investments in adaptable, compliance-ready architectures and processes.

1. Institute for Supply Management, 2025

2. Manufacturing.net, 2025

3. PWC, 2025

Executive summary

Resolution

Use resilience planning to prepare for all scenarios, now and in the future.

“79% of industrial leaders with formal resilience-tracking programs feel prepared for future disruptions.”

McKinsey & Company, 2023

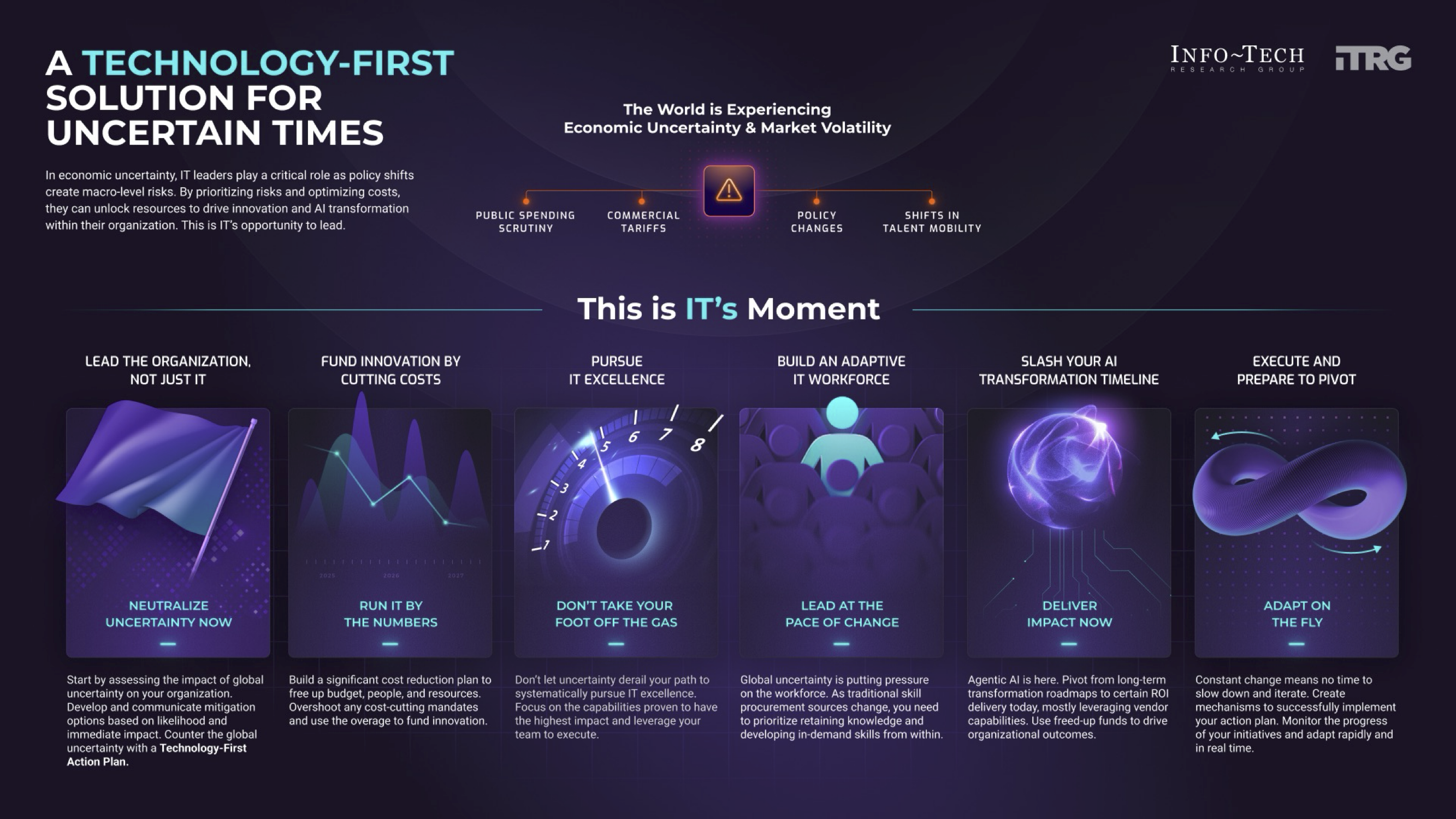

Explore the entire suite of research that supports these pillars by visiting our research center IT’s Moment: A Technology-First Solution for Uncertain Times.

-

Lead the Organization, Not Just IT

Neutralize Uncertainty Now -

Fund Innovation by Cutting Costs

Run IT by the Numbers -

Pursue IT Excellence

Don’t Take Your Foot off the Gas -

Build an Adaptive IT Workforce

Lead at the Pace of Change -

Slash Your AI Transformation Timeline

Deliver Impact Now -

Execute and Prepare to Pivot

Adapt on the Fly

Info-Tech’s Approach

- Phase 1 – Assess Uncertainties and Opportunities

- Phase 2 – Review Budget, Staffing, and Contracts

- Phase 3 – Build Your Technology-First Action Plan

- Phase 4 – Get Ready to Execute!

1: Lead the Organization, Not Just IT

Neutralize Uncertainty Now

- Defuse Uncertainty Drivers: Understand organizational impact.

- Lean Into the Curve: Apply Exponential IT.

- Pick Your First Bets: Deliver use cases now.

- Claim Your New Mandate: Technology-first or go out of business.

- Get the Word Out: Tell the entire organization now.

Start by assessing how global uncertainty is impacting your manufacturing operations, from supply chain volatility and energy market shifts to regulatory complexity and workforce disruption.

As CIO, map these risks to critical systems and processes and define mitigation strategies based on both likelihood and operational impact. Lead with a technology-first action plan that reinforces IT resilience, enables flexible production, and delivers real-time visibility across your value chain.

Digital twin technology offers manufacturers unprecedented visibility, predictive capabilities, and efficiency.

“By creating a digital replica of the entire supply chain, companies can monitor and track every aspect of their operations in real-time.

“Such visibility enables supply chain managers to identify bottlenecks, predict disruptions, and make informed decisions to optimize performance.”

Source: Maersk, 2025

2: Fund Innovation by Cutting Costs

Run IT by the Numbers

- Don’t Bet the Farm: Set the innovation budget.

- Find Real Dollars Quickly: Cut costs now.

- Demonstrate Technology Impact: Benchmark spend and shift.

- Shorten the Cycles: Build a flexible budget (finally).

- Sharpen the Pencil: Renegotiate vendor contracts.

Develop a targeted cost reduction strategy focused on rationalizing legacy infrastructure, consolidating applications, and automating routine processes to free up budget, talent, and capacity.

Exceed mandated cost-saving targets where possible and strategically reinvest the surplus into innovation initiatives that enhance digital capabilities, operational flexibility, and long-term competitiveness.

Predictive maintenance, powered by AI and advanced analytics, transforms maintenance approaches.

“Studies show that unexpected downtime accounts for up to 50% of all maintenance-related costs, costing manufacturers an estimated $50 billion annually worldwide."

...

“Companies [that adopt predictive maintenance] often experience:

- Up to 50% reduction in unplanned downtime …

- Approximately 30% lower maintenance costs …”

Source: AeoLogic Technologies, 2025

3: Pursue IT Excellence

Don’t Take Your Foot off the Gas

- Get the Baseline: Understand your maturity.

- Focus on What Really Matters: Improve your critical capabilities.

- You Can’t Do IT Alone: Guide your team.

- Enable Everyone: Provide tools and training.

- Aim High Selectively: Leapfrog for impact.

Stay the course on building IT excellence, even amid volatility. Prioritize high-impact capabilities, such as plant connectivity, real-time analytics, cybersecurity, and supply chain integration, that directly support operational performance.

Mobilize your IT team around clear execution goals that strengthen core manufacturing processes while laying the foundation for long-term digital maturity.

Establishing a centrally controlled supply chain delivering end-to-end visibility will be key to resilience.

“Even though over 57% believed effective supply chain management to be a competitive advantage and gaining such visibility had become the third-highest priority for all firms, only over 6% of responding organizations had accomplished their targets for end-to-end supply chain visibility.”

Source: Bridgenext Think Tank, 2024